Packaging design pillars. An exact science that can get the sales of a product through the roof. Find out how to hit the stars in 5 steps with Packly

Packaging design pillars. A topic that we are all familiar with, but do we really know the basics behind its function? Packly, your go-to partner for boxes, cases and containers, takes you on a journey through the guiding principles of packaging design to hit your sales target.

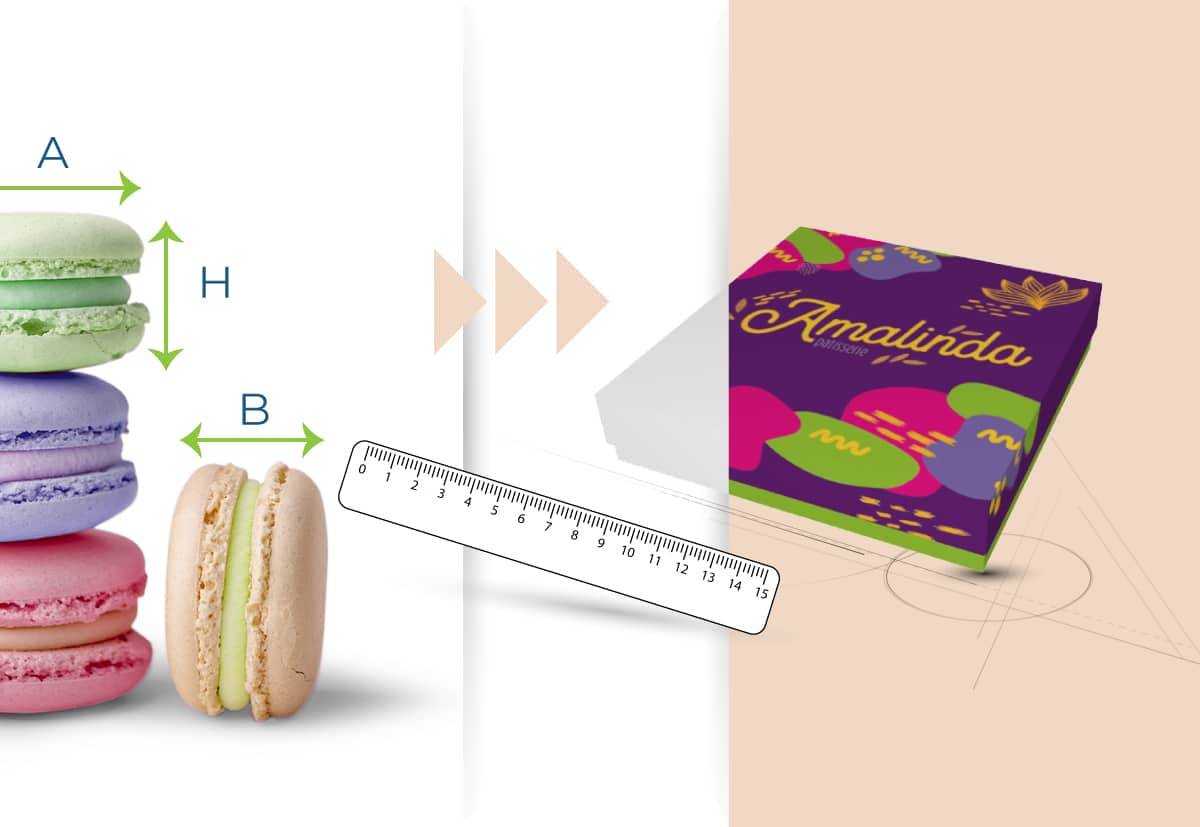

1. Shape and dimensions of the box

For an effective packaging design, you should prefer regular shapes that are easily positioned on the shelf. Just come up with the exact dimensions to contain the product without creating empty or useless space, thus also limiting waste. Some producers keep boxes the same size while decreasing the contents, in order not to increase product prices visibly. This is some practice that we strongly advise against though. Better user experience should be favored instead. Consumers will appreciate that there is no unnecessary packaging or overestimated room to trick them into believing there is more product inside.

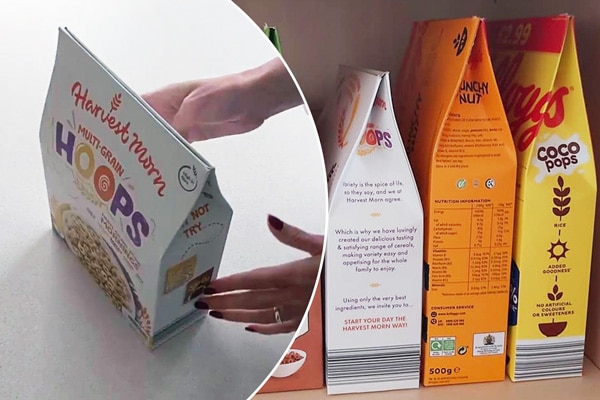

2. The right model

Before starting the design phase, you should choose the box model that best suits the product to be packaged. There’s more. The way in which the box is filled must also be considered. For example, for very small quantities, the tuck end box may be fine, but for larger quantities, it is better to go for the automatic bottom, which closes much more quickly. For even higher productions, the next step may be a model with flaps to be glued. This type of box, often used in the pasta sector, is formed and filled using a special cartoning machine as shown in the picture.

3. The best possible functionality

When designing the box, you should be mindful of:

– Who will have to fill it to speed up the boxing phase

– Who will have to store it by facilitating the stacking

– Who will have to use it keeping in mind a possible reuse of the packaging.

4. Sustainability since the design phase

Cardboard is certainly the choice of material that is most environmentally friendly. Packaging printed by Packly is 100% recyclable and compostable. The cardboard and digital printing inks used are certified for composability, both domestic and industrial. The materials have been certified by TUV Austria (“OK Home Compost” and “OK Industrial Compost”) so that waste packaging can be recycled through composting and biodegradation in accordance with the most important standards, such as the EU regulation EN 13432.2. Furthermore, packaging is produced using 60% of energy from renewable sources. We could go so far as to call ours organic packaging altogether.

5. Impactful design with special finishes

Packly offers a wide range of finishing and embellishments such as spot varnish and gold or silver foil. These elements must be used wisely and sparingly as they need to place a spotlight on the product, without overwhelming consumers. The additional processes should not become invasive or redundant, but they should rather serve to better emphasize the characteristics of what we are trying to sell.

Conclusions

Are you ready to create the perfect customized packaging design for your product? Choose the most effective solution in our catalog, apply the desired features and just order the prototype, single or large-run. Packly will support you throughout the production with convenience and competence!