Create professional packaging for paper industry is simpler than you think. In this post we want to show you how to deal with every phase of the project in order to simplify the creation process of your custom boxes.

Here are 5 basic steps to help you create professional packaging, from cradle to grave:

1. Customer briefing

This is a crucial phase to obtain good packaging results, it consists in collecting all the customer requirements. How? You can do that focusing on product features so that you can create an optimal packaging. You have to ask your client detailed information about:

– Material features of the product (dimensions, weight, volume, types of materials, …)

– Immaterial features of the product (price, market position, sales channel, product type and category, …)

– Mode of distribution (mode of transport and distribution, eg. offline or online purchase, warehousing, …)

– Targeting (moments and ways of consumption/use, uniqueness of the product and target; eg. when a product could be used in several moments or ways, you could realize two different types of packaging that fit with the different moments of use)

– Regulations (any legal obligations that packaging must respect; eg. nutritional tables on food products, age of use on toys, technical information when required, …)

– Competitors (who are the competitors, which are the material and immaterial features of their products, what is their current package, their communication strategy, …)

2. Concept creation

Once you’ve collected all the customer information you can start designing a packaging concept and determine the appearance of the boxes: dimensions, graphics, text, die-cut shapes, material, …

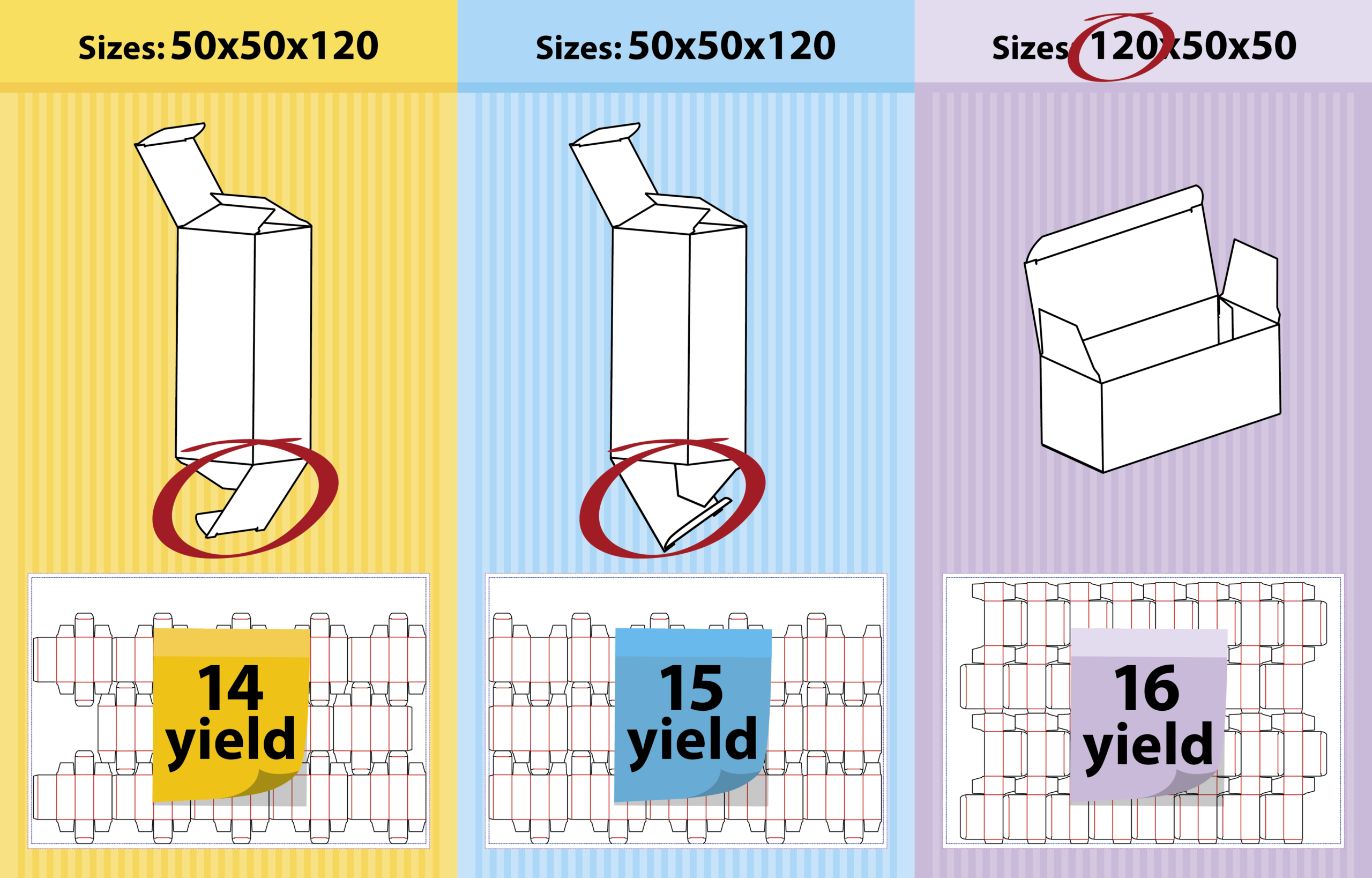

For large print runs it is really important to evalute the ideal dimensions of the packaging in order to optimize the yield on the press sheet and the overall dimensions for the distribution.

Optimize sizes: if the customer distributes products on pallets you should optimize the sizes of the packaging according to the secondary packages so that the load on pallets will be optimized too. That means a significant savings for your customer. Eg. if you have to design packages for biscuits you can try to change the arrangement of the products inside the box, the die-cut shape or the opening system (not forgetting the runnability).

Optimize yield: you can optimize the yield making maximum use of the space available on printing sheet by editing only some of the packaging aspects (eg. moving the opening flaps) without changing the box sizes.

Examples of optimized yield by moving the opening flaps.

3. Mockup creation

Once you have defined your project idea, you can request a mockup that allows you to show the customer your packaging, exactly as he will receive it.

Printed mockup: you can order an high quality printed mockup made with the same materials used in the final production so that you can test the structural aspects of the packaging, such as ease of opening, materials, weight capacity. You can also order different kinds of boxes so that you can choose the best solution with your client.

Virtual 3D mockup: you can share the interactive virtual 3D mockup with your client to have a preview of the final packaging graphics included. The virtual mockup allows you to rotate your box 360° in all directions and visualize your packaging from different angles. This is the best solution to speed up the packaging prototyping process saving a lot of time.

4. Market test

You can now test the market validity of your product – according to your client – with a small budget. In fact Packly allows you to order a miniseries of your packaging ( eg. 10, 100, 500) to evalute different graphic designs, promotional messages and boxes in different shapes. Market tests help you understand which are the packaging preferred by offline customers so that you can order them.

Packaging miniseries designed to market test.

5. Order

After doing all tests you only have to place the order. Packly has no minimum order: utmost freedom and flexibility for your packaging needs.

The best way to afford the creation process of professional packaging is to immediately identify customer’s needs and learn all about the product, so that you can design the best packaging solution optimizing costs and resources and offering custom solutions to the customer and attractive packaging to the consumer.