In our daily article, we suggest some guidelines to easy create cutting paths for windowing and holders.

Packaging design requires strong technical skills that could be gained only through accurate studies and after years of practical experience in this specific area. To generate a proper and workable die-cut template you should have huge knowledge about the technical details of the material used, the most suitable processing techniques and – above all – the limits and the potentialities of the machinery at your disposal.

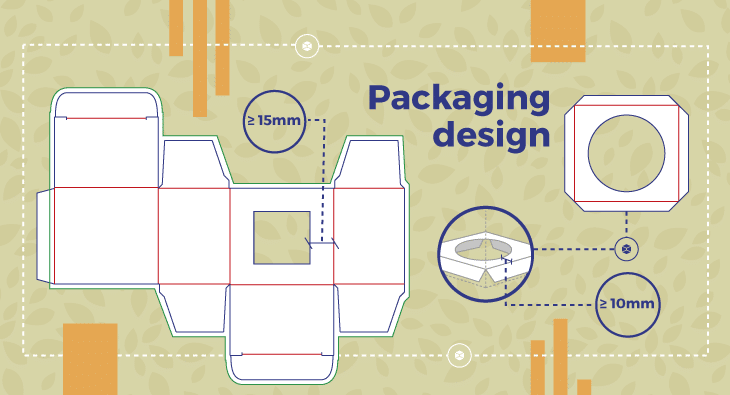

Once the tricky part of generating die-cut template is completed – process that happens automatically on Packly only by entering your custom sizes – you could need to add to the packaging template windowing and holders to clamp the products inside the packages.

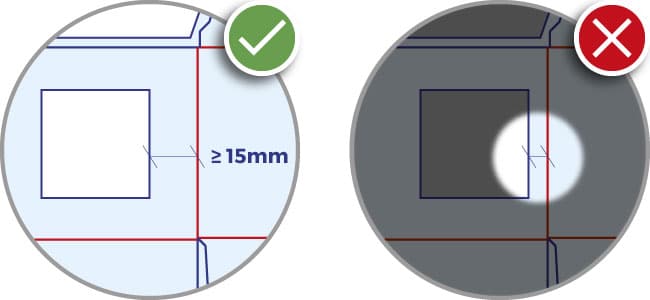

The position of the windowing is influenced by the packaging structural strength, by its machinability and the need to apply – or not to apply – a plastic film on the opening. Large windows, corner or on three sides windows weaken the structure of the box and can cause problems during the different production phases, in particular during the folding and gluing process, but it depends on the technical specifications of each machine. Whereas, the application of the plastic film requires a minimum distance from the edge of the window to ensure adequate gluing.

To meet all the prerequisites above, we recommend to place the windowing cutting path (of any shape) at a minimum distance of 15mm from the folding and cutting lines. Except for corner windows that need a sufficient quantity of material at the opposite corner and the application of the plastic film to compensate for the loss of strength caused by the large opening.

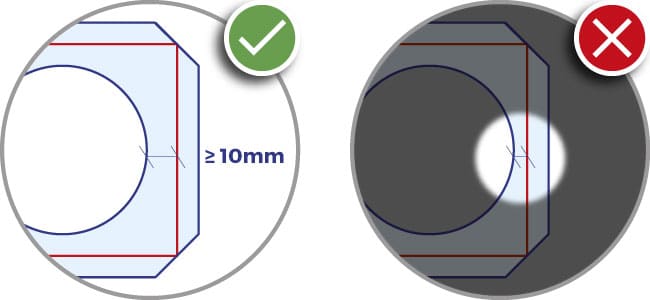

The design of the holders also requires a particular attention to the distance between the carving and the folding lines. Carved shapes too close to the edges could lead to assembly problems: paper breakages or bendings. These are the reasons why the minimum distance of the cutting lines from the creases has to be minimum 10mm. In most cases, this distance guarantees a good strength of the holder and limits the possibilities of breakages also facilitating the production and assembly processes. The internal inserts should be a little bit smaller than the internal sizes of the boxes because of the material thickness. If the paperboard thickness doesn’t exceed 0,5 mm, the sizes might be reduced of 0,5 mm circa. By slightly reducing the sizes the inserts will comfortably fit the boxes.

These instructions are technical tips generally valid for the design of windowing and holders but they need to be always verified case per case to be sure of their effectiveness.